foam-free insulated concrete forms (ICF)

FOUNDATIONS: MATERIALS ENCYcLOPEDIA

Applications for this system

Perimeter Beams

Basement walls

Frost walls

Basic materials

Cement binder

Wood fibre

Rock wool insulation

Poured concrete

Rebar

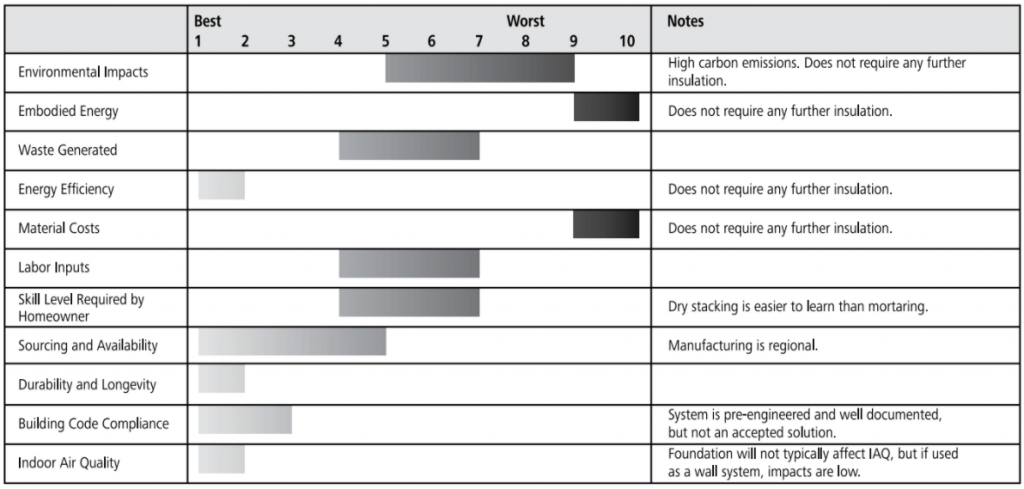

Ratings Chart for ICF Foundations

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

ICF System

There are many kinds of insulated concrete forms (ICFs), and the majority of market share is held by ICFs made of foam insulation. Durisol and Faswall ICFs, however, are made from cement-bonded wood fiber.

As with all ICFs, Durisol and Faswall blocks are made from a relatively lightweight insulative material with hollow cores. Blocks are dry-stacked in running bond on a poured concrete footing. Rebar is placed horizontally between alternate courses and vertically in every core. Concrete is poured into the cores of the completed wall forms in a single lift.

The wood fiber content is “mineralized” by removing the sugars from the wood and rendering it inert before it is bound with portland cement.

Blocks are available to create a variety of different finished wall widths and insulation values.

Environmental Impact Rating

Harvesting — Moderate

Limestone for portland cement is mechanically extracted from quarries and can have moderate to high impacts including habitat destruction and ground and surface water contamination.

The wood fiber is reclaimed waste wood from other industrial sources. Its impacts are mitigated because it is being reused.

Manufacturing — Moderate to High

The creation of portland cement is a high-intensity process, with limestone being heated in kilns to very high sustained temperatures. Fuels used include natural gas, oil, coal, landfill waste and coal, in large quantities, with impacts including significant air pollution and very significant greenhouse gas emissions. Portland cement makes up about 15 percent of the block by volume.

The wood is mineralized in a water bath, and heat is applied to dry the mineralized wood, requiring the use of fossil fuels. Mineralized wood makes up about 85 percent of the block by volume.

Transportation — Moderate to High

Sample building uses 4,160 kg of ICF blocks:

6.24 MJ per km by 15 ton truck

3.9 MJ per km by 35 ton truck

Sample building uses 19,032 kg of concrete:

17.9 MJ per km by 35 ton truck

Blocks are manufactured at a small number of centralized plants and shipped across the continent. They are a high-volume, heavy material and impacts rise proportionally with distance traveled.

Waste: moderate

Recyclable — Metal reinforcement bar.

Landfill — Block offcuts, insulation offcuts, mortar bags/pails.

Chart of Embodied energy & carbon

Energy Efficiency: high

Durisol and Faswall foundations can have a reasonable level of thermal performance, ranging from R-8 to R-28, depending on block thickness. The lightweight wood/concrete mix contributes to this performance, but it is largely achieved via mineral wool insulation inserts built into the blocks.

Material costs: high

ICF blocks are a relatively high cost option, but the cost includes the highest level of insulation available from a foundation material in this book. Compared on a whole-system basis, the cost would be similar to many other options.

Labour Input: moderate

The lightweight blocks are laid dry in a straightforward stacking process. The blocks can be cut and shaped with standard carpentry tools. Each block is 60 cm (24 inches) long and 30 cm (12 inches) high, resulting in a relatively fast stacking process.

Skill level required for homeowners: moderate

Placed on a level footing, no special skills are required to build this type of form wall. After the first course, no mortar or glue is used between blocks. Most owner-builders can competently build a Durisol or Faswall foundation, though bracing the walls and managing the concrete pour can present challenges.

Sourcing & availability: Easy

Durisol and Faswall are not very common in North America, with only a handful of plants producing blocks. Availability varies regionally, with the blocks being a special order item in areas further from production facilities. Check with the manufacturer for distributors in your local area.

Durability: High

There is a seventy-year history of cement-bonded wood fiber being used to build foundations, and reports and studies generally point to excellent performance in the field. Lifespan can be over a hundred years.

Code compliance

Cement-bonded wood fiber ICFs are not an approved solution in most codes, but as they use reinforced concrete and have well-documented standards from the manufacturer, they are likely to be accepted as an alternative solution.

Indoor air quality: n/a

As a foundation system, Durisol or Faswall blocks will have little direct impact on indoor air quality. The greatest impact on IAQ will be their role in helping to keep the floors and walls of the building high and dry. However, these blocks are also used for wall systems, and have excellent indoor air quality ratings in those applications.

Resources for further research

“Durisol Materials.” Durisol Building Systems Inc RSS. N.p., n.d. Web. 20 Apr. 2013.

“Faswall® Green Building System.” ShelterWorks Ltd. N.p., n.d. Web. 20 Apr. 2013.

Future development

Versions of this product have been in production and use since 1934. The basic product and construction process have not undergone much change in that time. The use of high-compression mineral wool insulation has added a higher degree of energy efficiency. Advancements in ecological cement production or replacement would have positive impacts on the blocks and the concrete used to fill them.

Tips for a successful ICF foundation

Durisol and Faswall provide installation instructions for their blocks, according to published standards, so these are not detailed here.